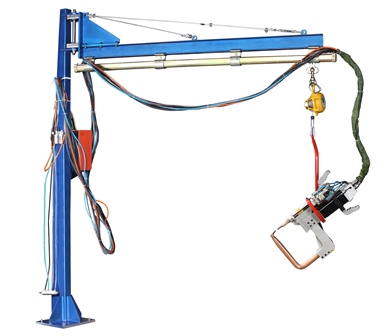

DN2 Series Haqnging Spot Welder

Machine features:

1. The suspended spot welder, also known as the integrated spot welder, consists of welding tongs, welder transformers, welder controllers, water cooling systems, pneumatic pressurization systems, and (suspension devices). Compact structure, convenient maintenance, small size and light weight greatly reduce the labor intensity of workers and save energy.

2. The electrode arm is made of high quality chrome zirconium copper to ensure the stability of the welding performance and the service life of the welder and the strength of the electrode arm.

3. The gas path system has a large diameter and is equipped with imported pneumatic components to make the welding tongs move quickly and improve production efficiency.

4. When welding, the heating time is short, the heat is concentrated, no arc, no spark splash, no welding slag, no welding and welding, no deformation of the weldment. In addition, after the innovation of the welding machine, the diameter of the pneumatic system increases, so not only the welding productivity is high, but also the energy consumption is low (72.3% of electricity saving), and the weldment has a beautiful appearance and good quality.

5. Welding is done by the proper combination of electrical resistance and mechanical force, so that high-strength and high-quality solder joints of the weldment weld nugget can be obtained.

6. The welding process is simple, does not require filling materials and solvents, and does not require shielding gas, so the cost is low.

7. The welding spot has high current density and high temperature. Therefore, after the welding machine controller precisely controls the energization time, the solder joint has a reproducible nugget size, so it can adapt to many types of homogenous or dissimilar metals and coated steel sheets. Welding.

8. The thyristor conduction angle is changed by the welder controller to perform heat adjustment, so that it is easy to mechanize and automate, so it can be matched with the robot for fully automated welding operation.

9. Different sizes and shapes of welding tongs (C type and X type) and shaped electrode heads are available for customers to choose according to different materials, different thicknesses, different shapes, different working positions and different process requirements.

10. The integrated spot welding machine is equipped with a suspension device, which can move and rotate in any direction of up, down, left, right, front and back in X, Y and Z three-dimensional space. The operation is extremely light and flexible, and it can realize all directions and omnidirectional Welding operation.

11. Can weld a variety of low carbon steel, low alloy steel, stainless steel, galvanized steel, sheet and round steel. Widely used in automobiles, rolling stock, security doors, cabinets, household appliances and construction, wire mesh spot welding and other industries.

no